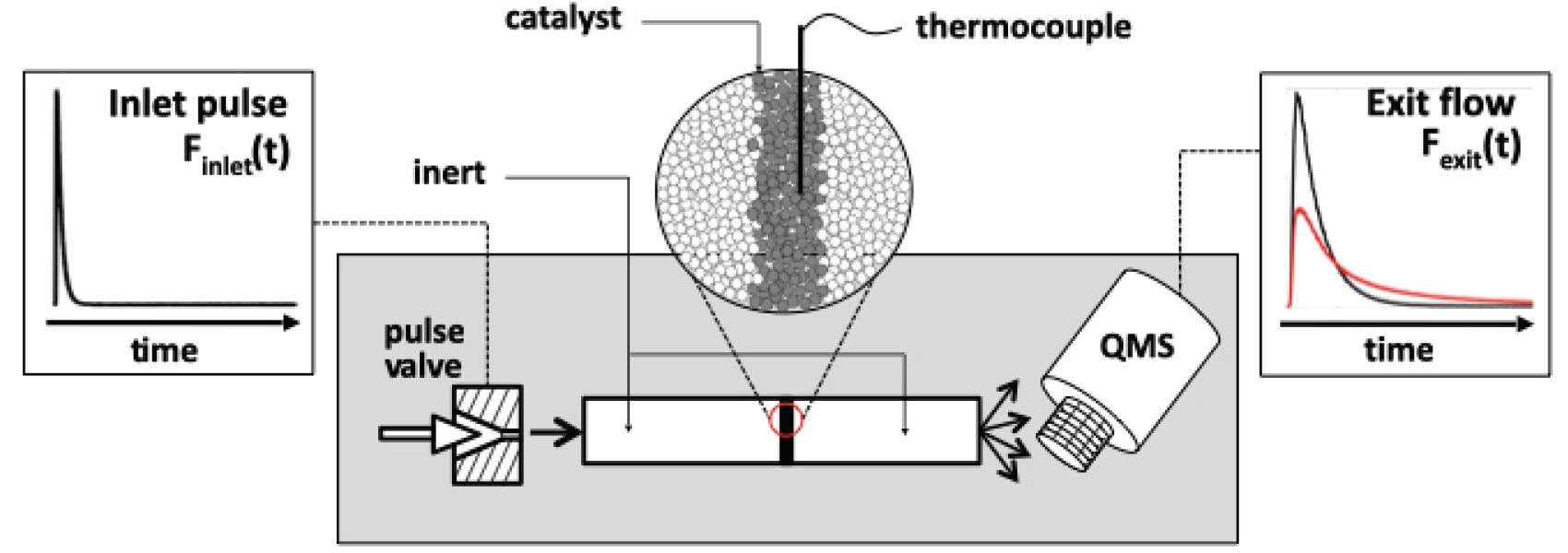

A TAP reactor is a sophisticated vacuum transient response apparatus used to investigate gas-solid interactions. It measures probe molecule pulse responses, which can be analyzed to unravel the detailed reaction mechanism and kinetics of catalytic process on complex catalytic materials. These insights can be leveraged for the development of tailored catalytic materials for industrial processes. The faculty in the Cullen College of Engineering have TAP expertise and can assist in tackling a wide range of catalysis problems.

EXPERIMENTAL CONFIGURATION

TAP experiments use a packed-bed microreactor holding a thin-zone of catalyst material that is placed in vacuum. An extremely small and narrow pulse of molecules (~10 nmol) is injected into the reactor by means of high-speed pulse valves and the exit low is detected by means of a high-resolution mass spectrometer. The small pulse size allows the user to probe the kinetic state of the material from pulse to pulse without inducing a significant change to the surface state of the material. If desired, the state of the catalyst can be precisely altered, for example, from oxidized to reduced state, over an extended period of pulsing. Observing the evolution of the kinetic properties from the TAP data can reveal how “hidden” processes such as bulk transport, surface diffusion, site blockage, reaction products, and surface intermediates impact the reaction mechanism. This information can be used to study deactivation mechanisms or to distinguish why materials of similar composition and preparation behave differently at process conditions.

PUBLICATIONS

- K. Morgan, N. Maguire, R. Fushimi, J.T. Gleaves, A. Goguet, M.P. Harold, E.V. Kondratenko, U. Menon, Y. Schuurman, G.S. Yablonsky, Catal. Sci. Technol. 2017, 7, 2416-2439.