In the Grabow Group, we use innovative strategies to design catalysts that can perform dehydrogenation more easily, efficiently, and economically. A reactant molecule that has always attracted us, partially due to our location in Houston, is methane. It is notoriously difficult to selectively activate methane, particularly at reasonable temperatures; there are still no major industrial processes that directly convert methane into upgraded chemicals without an intermediary step. Some of our strategies to selectively activate methane include the use of single-atom alloys, which can draw oxygenate adsorbates to the metal surface that assist in the C-H bond cleavage, and applied electric fields, which preferentially binds certain molecules and adsorbates and affects the activation barriers for methane activation. These strategies move us closer to realizing a catalyst that can achieve one of the “holy grails” of catalysis – the direct upgrade of methane.

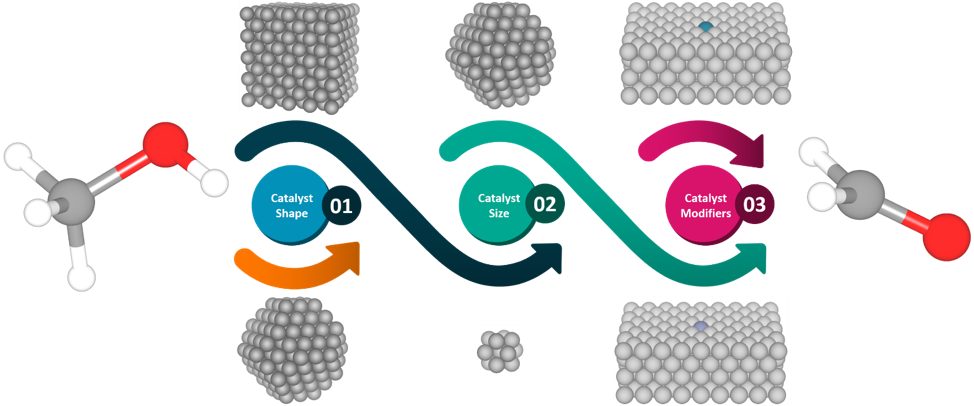

We are also developing improved catalysts for the conversion of methanol to formaldehyde. This well-established reaction, often known as the Formox process industrially, uses silver metal as the catalyst. In the Grabow Group, we use a multi-faceted approach to improve our methanol-to-formaldehyde catalysts. First, using density functional theory (DFT), we study different dopants in Ag-based single-atom alloys to understand how they affect the binding of methoxy intermediates and improve the activation ability of the metal surface. Second, we look into Cu and Cu-based single-atom alloys as a cheaper alternative to the industrially-prevalent Ag catalysts. Lastly, by coupling our first-principles calculations with kinetic Monte Carlo simulations, we can predict the optimal reaction conditions and sizes and shapes for our catalysts. Through this approach, we come closer to bringing our theoretical predictions to an experimental reality.

Lastly, we are also intrigued by the other product of dehydrogenation reactions: hydrogen itself. Hydrogen has great potential to be used as a fuel if it can be stored and produced on-demand. The hydrogen evolution reaction (HER) occurs on the cathode of a fuel cell, where protons (H+) are obtained from the electrosplitting of water and combined to form hydrogen gas (H2). Platinum metal has been found to be the best catalyst for this reaction, but using DFT, we aim to find alloys and other possibilities using non-precious metals in hopes to produce a cheaper alternative for catalyzing the future of fuel.

Publications:

- Goulas, K. A., Song, Y., Johnson, G. R., Chen, J. P., Gokhale, A. A., Grabow, L. C. & Toste, F. D. Selectivity tuning over monometallic and bimetallic dehydrogenation catalysts: effects of support and particle size. Catal. Sci. Technol. 8, 314–327 (2018).

- Schipper, D. E., Zhao, Z., Thirumalai, H., Leitner, A. P., Donaldson, S. L., Kumar, A., Qin, F., Wang, Z., Grabow, L. C., Bao, J. & Whitmire, K. H. Effects of Catalyst Phase on the Hydrogen Evolution Reaction of Water Splitting: Preparation of Phase-Pure Films of FeP, Fe 2 P, and Fe 3 P and Their Relative Catalytic Activities. Chem. Mater. 30, 3588–3598 (2018).

- Zhao, Z., Qin, F., Kasiraju, S., Xie, L., Alam, M. K., Chen, S., Wang, D., Ren, Z., Wang, Z., Grabow, L. C. & Bao, J. Vertically Aligned MoS 2 /Mo 2 C hybrid Nanosheets Grown on Carbon Paper for Efficient Electrocatalytic Hydrogen Evolution. ACS Catal. 7, 7312–7318 (2017).

- Zhao, Z. et al. Bifunctional metal phosphide FeMnP films from single source metal organic chemical vapor deposition for efficient overall water splitting. Nano Energy 39, 444–453 (2017).

- Hsieh, M.-F., Zhou, Y., Thirumalai, H., Grabow, L. C. & Rimer, J. D. Silver-Promoted Dehydroaromatization of Ethylene over ZSM-5 Catalysts. ChemCatChem 9, 1675–1682 (2017).

- Goulas, K. A., Sreekumar, S., Song, Y., Kharidehal, P., Gunbas, G., Dietrich, P. J., Johnson, G. R., Wang, Y. C., Grippo, A. M., Grabow, L. C., Gokhale, A. A. & Toste, F. D. Synergistic Effects in Bimetallic Palladium–Copper Catalysts Improve Selectivity in Oxygenate Coupling Reactions. J. Am. Chem. Soc. 138, 6805–6812 (2016).